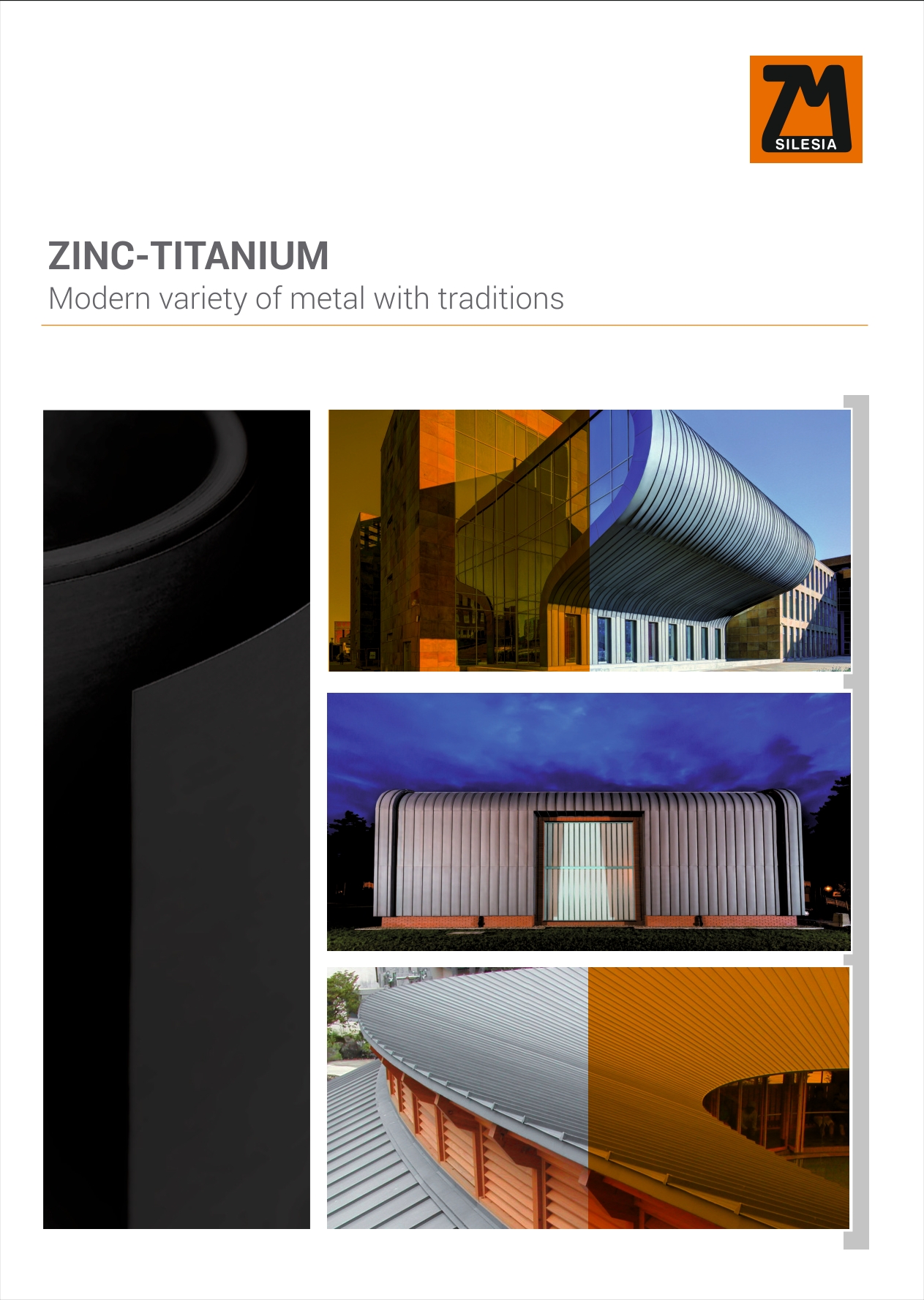

SilesiaZINC ZINC-TITANIUM SHEET

PRODUCTS

SilesiaZINC zinc-titanium sheet is manufactured in accordance with the PN-EN 988 standard and is available in three variants, differing only in the finish of the outer surface:

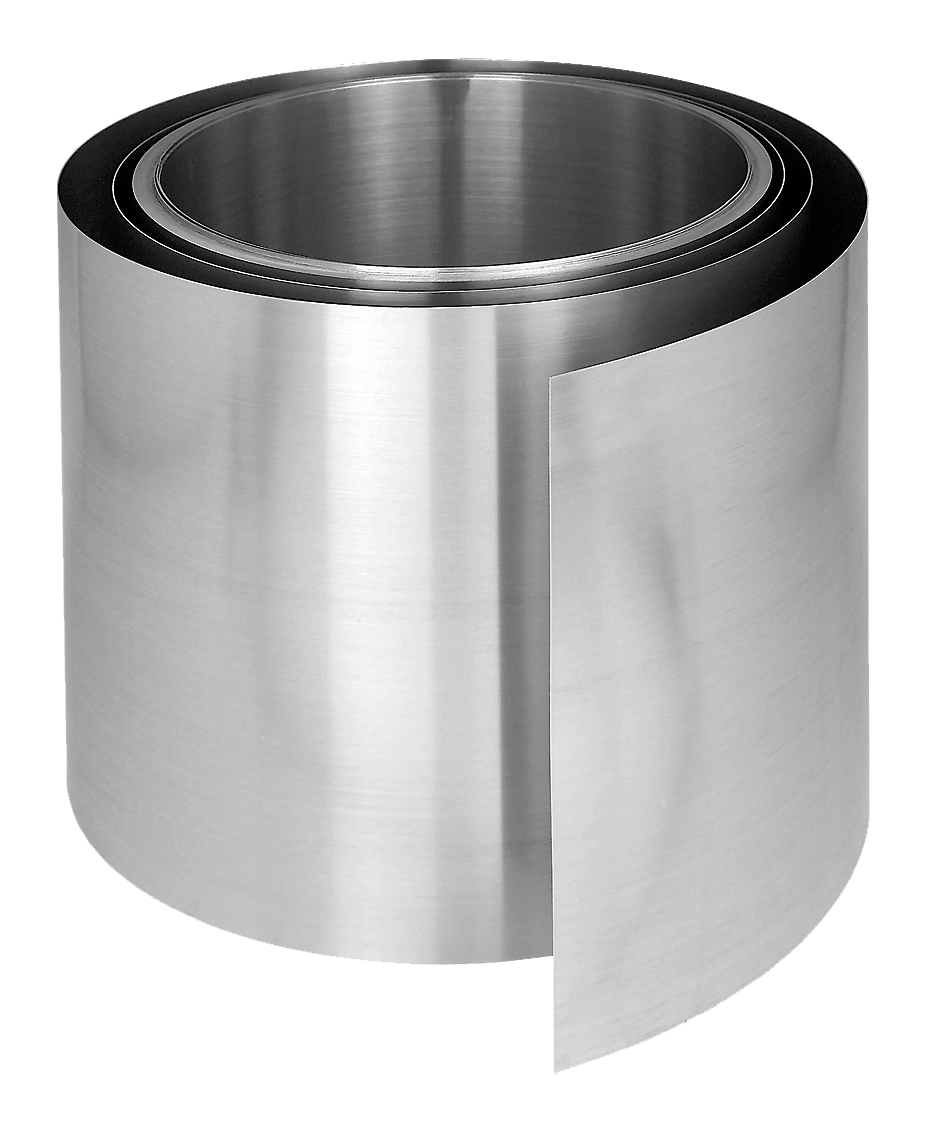

NATURAL – features a metallic, shiny surface that gradually develops a light grey matte patina over time due to exposure to atmospheric conditions.

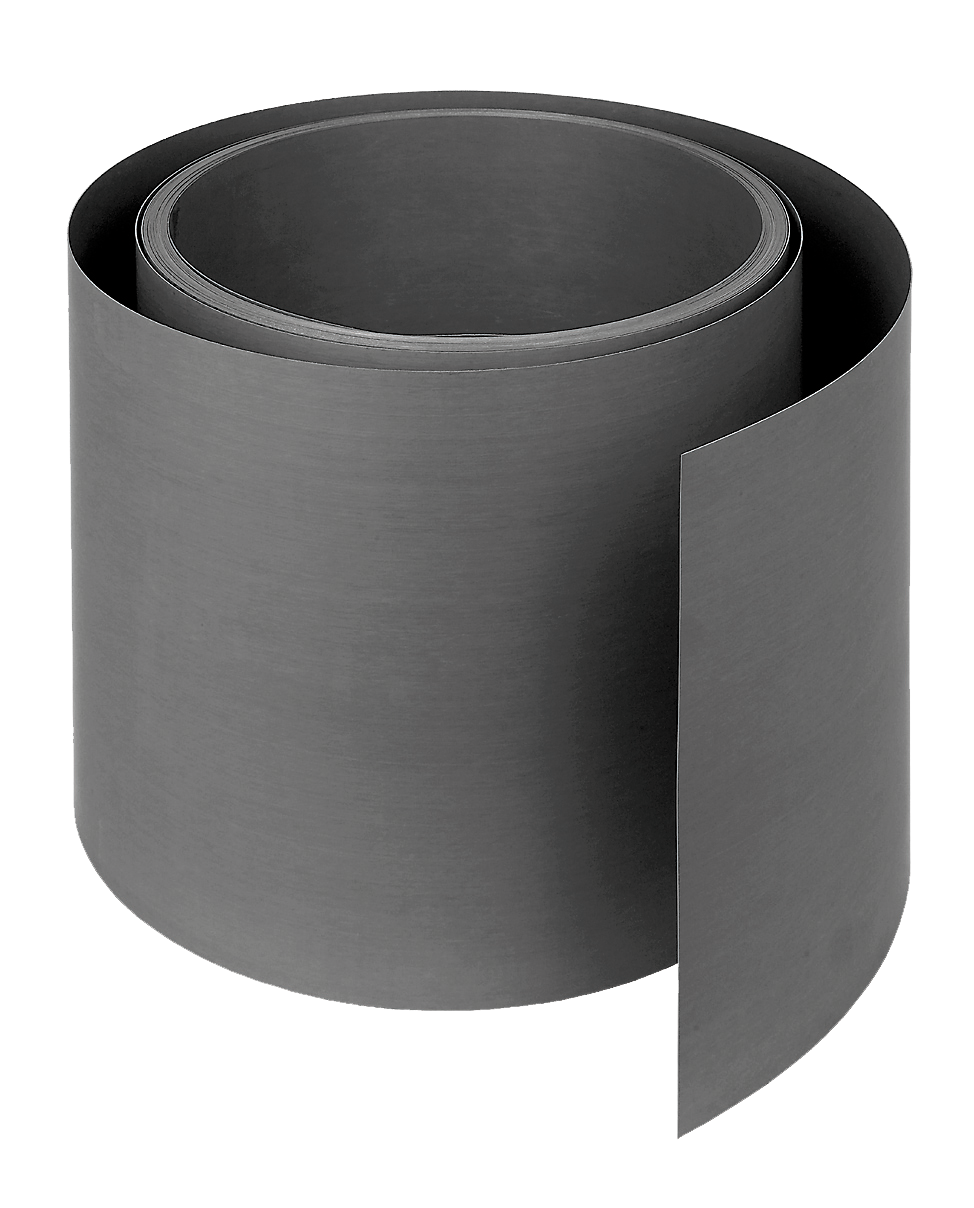

PRE-AGED GREY – features a matte, light grey surface with a patina created through a controlled chemical process. To avoid the transitional phase of natural patina formation, factory-patinated sheets are recommended for exposed architectural elements such as façades.

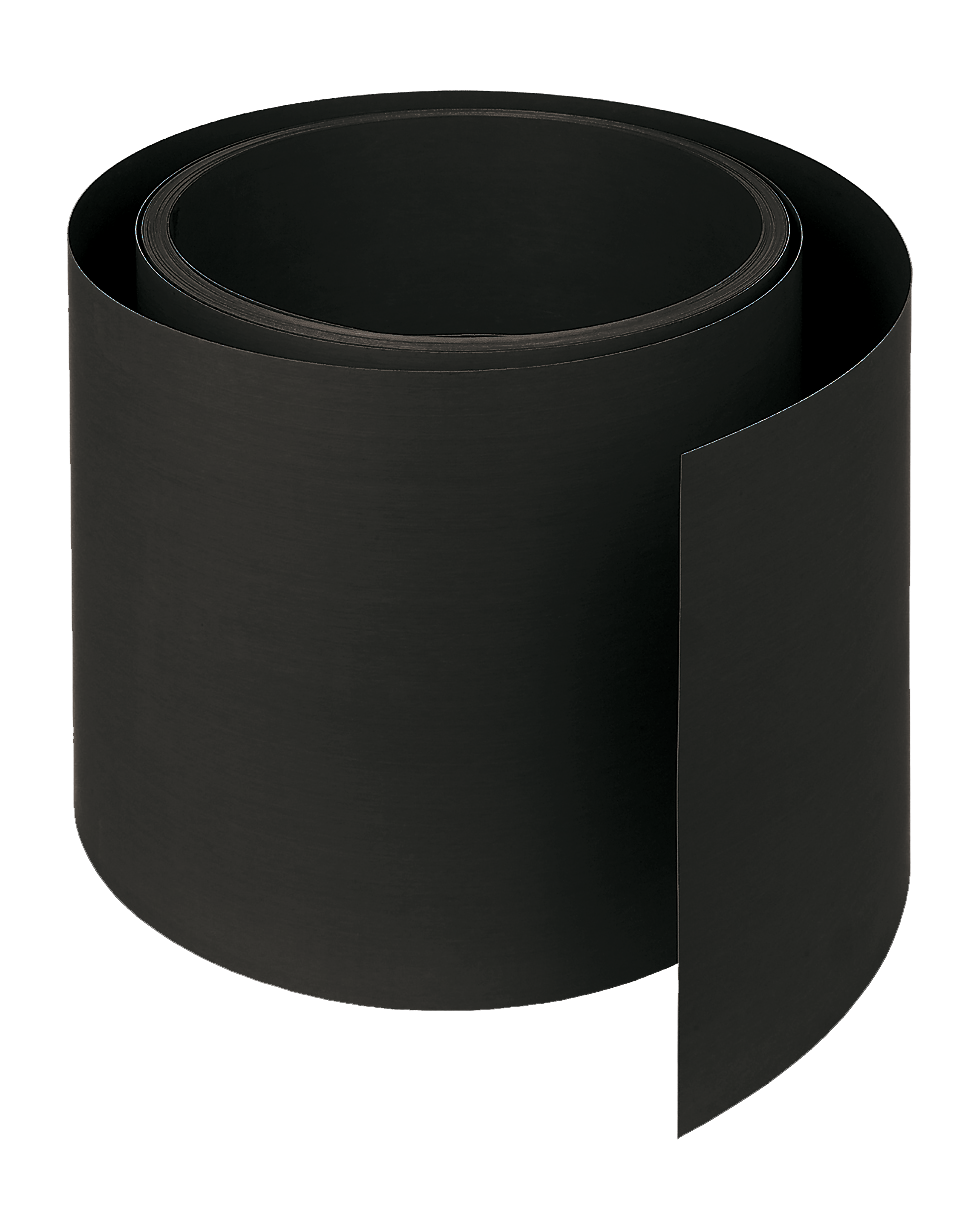

PRE-AGED CARBON – a new type of patina with a shade close to graphite black, created through a complex technological process. This material contrasts beautifully with lighter colors, giving buildings a unique and distinctive character. It pairs perfectly with other materials, such as natural slate.

Why Zinc-Titanium?

Durability – over 80 years

Maintenance-free

Corrosion-resistant at cut edges

Resistant to surface scratches

Does not require painting

Highly formable and easy to join

Non-magnetic

A natural and environmentally friendly material

Visually appealing

100% recyclable

A typical property of zinc is its ability to form a protective layer when exposed to atmospheric conditions. This gives the material an exceptionally long service life and makes it virtually maintenance-free.

On the initially shiny, rolled surface, a thin, tightly adhering protective layer—just a few micrometres thick—forms over time. This layer consists of zinc oxides and basic zinc carbonates and is commonly referred to as patina.

Wide Range of Applications in Construction

Zinc-titanium is a modern material produced from high-purity SHG zinc, containing a minimum of 99.995% Zn, alloyed with small additions of copper and titanium.

Thanks to advanced manufacturing technologies, the sheet exhibits excellent physical and mechanical properties and has a wide range of applications in the construction industry.

Zinc-titanium sheet is produced from Z1 SHG zinc in accordance with the PN-EN 1179 standard, containing at least 99.995% Zn. It is alloyed with titanium (0.06–0.2%), copper (0.08–1.0%), and aluminum (up to 0.015%).

The strip is continuously cast, rolled, and then cut into sheets or coils. Sheets and coils comply with the requirements of the PN-EN 988 standard.